Grainger Customers, Corporate, Group & Government Buyers - Learn about Wholesale Purchasing

-

Need Help? Get Support

-

Phone: 844-877-8326

Comparison of the Optima Steamer with a hot water pressure washer for barrel sanitation

.

.

Article by Debby Le and Stewart Lebrun of Lebrun Labs LLC

Published November 2019

Introduction

The Optima Steamer by Steamericas Inc. is a portable, compact system that generates a superheated vapor jet that can be precisely and efficiently directed toward environmental surfaces. Almost no water and no chemical residue are left behind. These attributes make the Optima Steamer the method of choice for a broad range of cleaning and sanitation applications. For example, Steamericas has fitted the steamer with precision hardware that attaches to a wine barrel to allow safe, hands-free barrel cleaning. This barrel attachment improves sanitation efficiency by increasing pressure in the barrel lumen. The combination of temperature and pressure has historically been utilized as an effective method of sterilization; however, a systematic assessment of the combination of temperature and pressure for wine barrels has not been conducted. After sanitation, oak wine barrels must maintain integrity so that they are suitable for wine aging. However, it is not clear what pressures and temperatures these barrels can withstand or can be achieved at different durations and intensities of steamer operation. In addition, wine microbes, while extremophiles, are not thermophiles and can be killed if the temperature reaches 80 °C. As many of these microbes can penetrate the barrel as much as 5 mm, this study sought to determine whether the Optima Steamer and/or a commercial pressure washer could subject the oak to 80 °C at a 5-mm depth.

Barrel setup and steam testing method

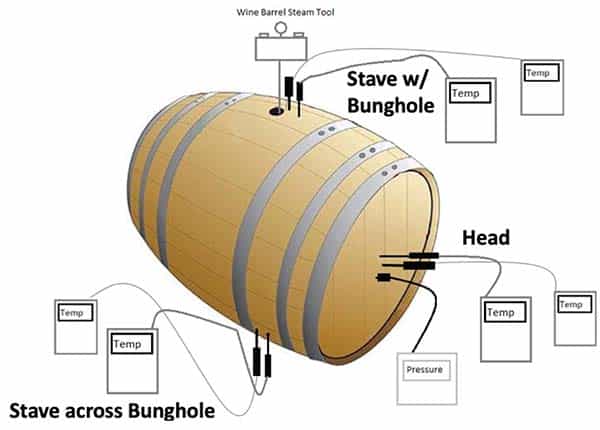

Used 60-gallon red wine barrels with similar hoop patterns and dimensions were purchased from Evans Family Barrels located in San Fernando, CA. Four-millimeter-wide holes were drilled into the barrel to insert temperature probes. A pressure meter was also inserted into each barrel. Figure 1 shows the locations of the holes. The steamer was fitted with the wine barrel attachment and placed into the bunghole. Steam was turned on, and temperature and pressure recordings were taken at set time intervals at three different locations. Temperature and pressure recordings were taken during the cooldown period for most tests.

Hot water barrel testing

A major US brand hot water pressure washer was used to fill the barrels with water, which was heated to 82 °C at the maximum safe setting. The washer’s wand attachment was inserted into the barrel and filled. The probe configu- ration was the same as shown in Figure 1 except an additional temperature probe was inserted to measure water temperature readings. To compare trials done with the Optima Steamer, all tests were performed for 60 minutes with temperature recordings taken every minute once the washer was removed.

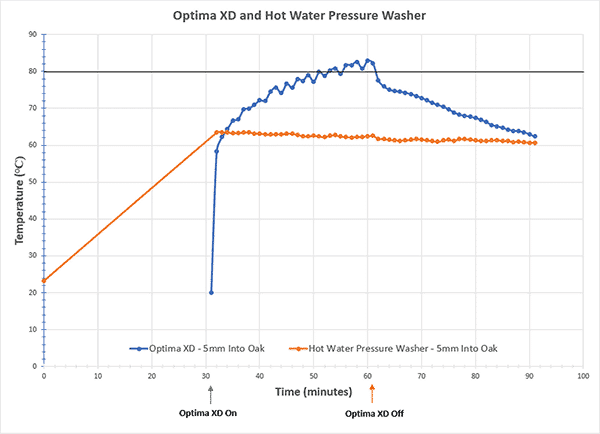

Figure 2. Temperature comparison between the Optima Steamer and a hot water pressure washer over time. Each point represents the average temperature of the head, side 1, and side 2 of the barrel. The temperatures are a theoretical value derived from calculating the average temperature on the inside of the barrel and average temperature 10 mm into the oak of the barrel. This theoretical value is represented as 5 mm into the oak of the barrel.

Results and Discussion

Spoilage yeast, including Brettanomyces spp. (“Brett”), penetrate wooden barrels and persist for years. Brett “digs” into wood by acid hydrolysis, which allows it to penetrate as deep as 5 mm or more; once there, it “hibernates” in empty barrels and is difficult to eliminate. When conditions change, Brett grows in the wine, entering log-phase growth, even under anaerobic conditions in high levels of alcohol. An unfortunate consequence is that Brett metabolites spoil the wine. In order to sanitize a wine barrel prior to wine aging, the barrel temperature must reach 80 °C within the wood. Other methods include the use of potentially hazardous chemicals, which can result in chemical residues within the finished wine. The wine industry is thus generally trending away from chemical methods. In this study, the Optima Steamer, fitted with a barrel tool, delivered superheated steam (110 °C) and increased pressure (5 psi) within the barrels, resulting in a higher temperature at a 5-mm depth within the wood than could be achieved using a commercial pressure washer. In addition, the temperature increase was faster with the steamer, with very little residual water within the barrel after treatment. Filling a barrel with hot water takes at least 30 minutes of operator time, and the barrel can only be drained by siphon after the water has cooled, effectively making filling barrels with hot water an all-day procedure. Water delivered by the pressure washer at the highest safe operating temperature was 80 °C, which resulted in a temperature of 60 °C at a 5-mm depth in the barrel. On the other hand, the Optima Steamer delivered the required temperature of 80 °C to kill spoilage microbes at a 5-mm depth into the wood after 23 minutes, and the small amount of residual water within the barrel was evacuated by rotating the barrel. The use of dry steam delivered by the Optima Steamer appears to be a practical, chemical free and effective procedure for wine barrel sanitation.