Grainger Customers, Corporate, Group & Government Buyers - Learn about Wholesale Purchasing

-

Need Help? Get Support

-

Phone: 844-877-8326

Optima Steamer™ SE-II

The SE-II all-electric, food grade dry steam generator offers an affordable solution for industrial sanitation with unrivaled power and performance compared to steamers in its class.

The Optima Steamer™ SE-II is the next step in dry steam technology, blending unmatched power and performance with simplified operation. This stainless steel all-electric steam generator produces powerful dry steam for industrial sanitization for food processing and various manufacturing needs. The SE-II operates on 3-phase electric power and is available in 3 models based on their performance: 18K (18000 watt), 27K (27000 watt) and 42K (42000 watt). ASME compliant models are also available.

The SE-II is designed for indoor industrial use and is ideal for:

- Food and beverage equipment and production line sanitization

- Manufacturing/CNC and HVAC cleaning

- Bacteria, yeast, mold and fungi elimination

- Winery and brewery equipment cleaning and sanitization

- Pharmaceutical and manufacturing cleaning and sanitization

Front View

Water Level Gauge

Pressure Gauge

Water Tank Cap

Power Switch

Steam Switch

Emergency Stop

Rear View

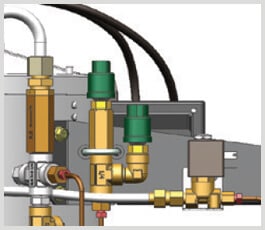

2 Steam Outlet Valves

Moisture Control Valve

Drain Valve

Quick Plug for Feed-Water

LCD Monitor

POWERFUL ALL-ELECTRIC PERFORMANCE.

See and feel the difference of the SE-II’s powerful heating system that delivers dry, superheated steam continuously at a rate of up to 58.8 kg/hr.

SMART LCD MONITOR CONTROL SYSTEM.

The SE-II’s CPU and LCD monitor make operation and maintenance simple. No clumsy touchscreen or complicated controls–turn it on and you’re steaming.

SIMPLIFIED OPERATION. RELENTLESS SAFETY.

The SE-II has been intelligently designed so it can be operated by almost anyone. With over 20 safety features, it takes the worry out of operation.

CONVENIENT CONNECTIONS.

The SE-II has 2 steam output connections standard with options available for more. Connect a water hose for an unlimited supply of water.

SANITIZE AND DEODORIZE WITH NO CHEMICALS.

The Optima’s superheated steam is lab-tested to kill mold, bacteria and viruses using only water. Sanitize while you clean and stop odors where they start.

REDUCE YOUR COSTS, SAVE THE ENVIRONMENT.

Get rid of harmful chemicals, reduce water consumption and cut wastewater with the Optima and save money while you’re saving the earth.

Food Processing

Adhere to FISMA requirements easily by sanitizing while you clean. Reduce chemical usage by cleaning with steam.

Wineries

Reduce water consumption, and clean naturally with dry steam. Sanitize and swell barrels and other equipment without chemicals.

Breweries

Protect your investments by cleaning and swelling foeders and barrels with steam. Ensure the purest product by eliminating chemicals.

Facility & Hospitality

Eliminate odors where they start by cleaning with steam. Quickly sanitizes surfaces, fabrics, cushions, and other high-contact areas with no waste water.

Pharmaceutical & Medical

Dry steam is lab-tested to quickly and effectively eliminate most pathogens. Sanitize while you clean with pure steam.

HVAC

Low pressure, high temperature steam can penetrate hard-to-reach nooks and crannies, and tackle harborage areas without waste water.

Included Accessories

| Part No. | Description | Quantity | ||

|---|---|---|---|---|

| 18K | 27K | 42K | ||

| 85-50356 | Steam Gun K26 with nozzle 3.5 | 1 | 1 | 1 |

| 85-50213 | Rubber protect steam hose PTFE 6-8.5, 10m | 1 | 1 | 1 |

| 18-83004 | Microfiber towel FBZ, Dark blue | 1 | 1 | 1 |

| 18-83005 | Microfiber towel Warp knitted, Dark blue | 1 | 1 | 1 |

| 18-83006 | Microfiber towel Wool, Dark blue | 1 | 1 | 1 |

| 23-33111 | Water probe sensor | 3 | 3 | 3 |

| 12-24022 | Water filter, ADMF 1212M (Electric Model) | 1 | 1 | 1 |

| 13-33021 | Fuse 5X20 4A 500VAC, CERM (Electric Model) | 2 | 2 | 2 |

| 22-22105 | Silicon tube 12 x 16, Nozzle protector 1M | 0.28 | 0.28 | 0.28 |

| 14-43033 | O-ring D.17.12 x 2.62 U115 | 2 | 2 | 2 |

| 14-43002 | O-ring D.21.89×2.62, U118 | 2 | 2 | 2 |

| 32-21061 | Couplings D. 1/2-5/8 PTC or | 1 | 1 | 1 |

| 85-50362 | Garden hose adapter PF3/4 (USA Only) | 1 | 1 | 1 |

| 35-50065 | Free Chlorine Water Check (EPA) | 1 | 1 | 1 |

| 35-50066 | Total Hardness- Preprinted Foil | 1 | 1 | 1 |

| Maintenance Tool Kit | 1 | 1 | 1 | |