Grainger Customers, Corporate, Group & Government Buyers - Learn about Wholesale Purchasing

-

Need Help? Get Support

-

Phone: 844-877-8326

HVAC

HVAC Cleaning with Steam

Use Powerful Dry Steam to Clean and Disinfect with Less Water

Revolutionary

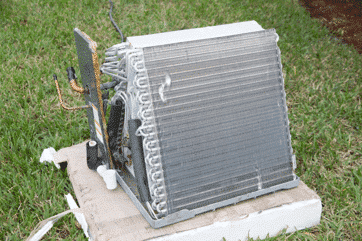

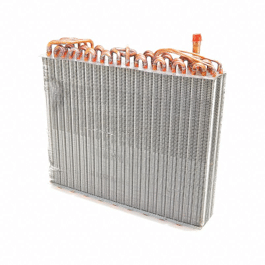

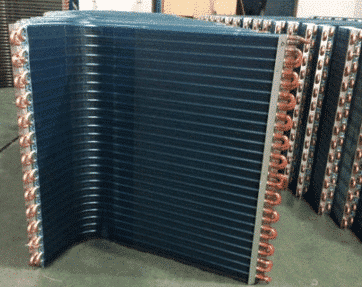

In all HVAC units the heat is either removed or added to indoor spaces by coils. Optimum heat transfer and system efficiency, is determined by how clean the coil surfaces are. Dirty coils is the primary source of problems in HVAC systems.

The air moving across the evaporator and condensing coils, will always contain dust, dirt, pollen, grease, and moisture. When the coils become blocked, they simply cannot provide its designed or even adequate heat transfer, and this will cost you in many ways.

Versatile

Dirty coils also create an excellent breeding ground for bacteria and mold, negatively impacting a building’s indoor air quality, and potentially the health of people indoors. In addition to the coils, the condensate pan is prone to the build-up of bacterial slime. If it doesn’t drain properly, it can become a breeding place for harmful bacteria and can cause significant water damage.

The lesson is simple, HVAC maintenance during the spring and fall (keeping coils and HVAC system clean) will reduce monthly electricity costs and the risk of expensive consequences.

Recommended Model: Optima XE Steamer

Efficient HVAC Cleaning

Greatly reduce facility downtime from HVAC cleaning and increase your production efficiency. Steam requires very little to no preparation prior to cleaning or sanitizing. The Optima Steamer is pressurized and heated to 352°F, making it ready to steam for all day use in as little as 6 minutes*. Reach hard-to-reach nooks and crannies, and tackle those harborage areas without generating over-spray or puddles of waste water.

Optima’s dry steam with gentle pressure can safely clean the most sensitive equipment components such as control panels, conveyor belts, HVAC coils and screens, walk-in coolers and freezers. Eliminate multiple steps of preparing, washing, soaping, rinsing, drying and cleaning up wastewater. Less downtime means more production and increased efficiency.

Download our HVAC Brochure for more information: HVAC Brochure.

Cleaning Applications

- Reduced water and chemical consumption

- No waste water runoff or overspray

- Chemical-free sanitation

- Increased sanitation (reaches into cracks and crevices)

- Save time and effort

- Deodorize and sterilize surfaces

- Clean hard to reach nooks and crannies

Benefits

- Three operators can clean at once

- 30’ (10m) of hose length (upgradeable up to 20m)

- Adjustable moisture control valve

- Easy to operate and maintain

- Reduce the need for chemical cleansers

- Automated boiler and safety features

- Quick dry time to prevent rust or corrosion

- Vapor will not damage surfaces, seals, motors, sensors or most electronics.

What Can Dry Steam Clean & Sanitize?

-

-

- Evaporator coils

- Condenser Coils

- Air Handlers

- Aluminum Grating

- Exhaust Hoods

-